AccuMix II™ tankless electric water heater is designed for handwashing solutions in public-use lavatories. All AccuMix II models feature an integrated ASSE 1070 mixing valve and are factory set not to exceed 105 °F for safe handwashing. The units are mountable in any orientation for a simplified, flexible installation. Silent operation is available on all models except for AM012240T. Mount the unit within two feet of the fixture for best performance.

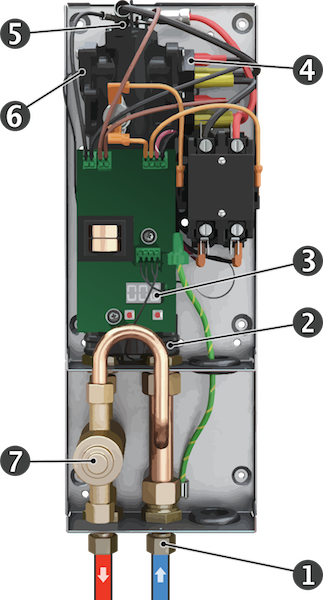

Water enters the heater through the 3/8″ compression fitting.

The inlet temperature and gallons-per-minute flow rate are measured and the data is sent to the control board.

The software calculates the amount of power to be applied to the heating element based on the inlet temperature, flow rate, and set temperature.

System status and operation feedback are communicated via the display.

Triacs modulate the power to the heating elements to achieve the correct output.

The heating elements activate and heat the outgoing water to the set temperature.

Outlet thermistor sends the hot water temperature to the control board. Self-modulating software compares the actual outlet temperature to the desired temperature and makes adjustments if required.

ASSE 1070 rated mixing valve ensures the outlet temperature is always within code requirements.